Eurofins E&E North America EMC Testing: Immunity Requirements

Eurofins E&E North America EMC Testing: Immunity Requirements

Eurofins E&E North America understands that EMC testing of your wireless devices and products is critical to your time-to-market and to the success of your product. Testing is important not just for the quality of the products you make, but for their safety and performance as well. Choosing an EMC testing lab for wireless devices is a key decision that your team can not afford to make lightly, and when to start the testing process is also key. We are a leader in EMC testing and the partner you need.

Why EMC Testing is Important?

EMC (Electro-magnetic Compatibility) testing as the name suggests is required to ensure that:

- A product does not emit unacceptable levels of electromagnetic interference (EMI)which can affect the functions of nearby devices.

- A product is not affected by or is immune to electromagnetic disturbances present in its intended environment of use and continues to function satisfactorily within a defined margin of safety.

A typical EMC testing program consists of a combination of EMI and EMC immunity tests.

When is Immunity Testing Needed?

Immunity testing is a regulatory requirement for all product categories if you are planning to market your product in the European Union. This type of testing is also critical for success if the product is intended for specific industries where reliable and safe operation of equipment is critical, for example, NEBS, military, avionics, and medical.

Your product must demonstrate that it continues to perform safely in the presence of various electromagnetic phenomena.

Basic Types of Immunity Testing

The immunity tests are generally divided into two categories based on the nature of the underlying electromagnetic phenomenon. These categories are continuous interference immunity tests and transient immunity tests.

While immunity requirements can vary significantly depending on the country and product type, there are certain basic immunity tests that are very common.

Continuous immunity tests such as Radiated Immunity, Conducted Immunity, and Magnetic Field Immunity involves stressing the product to continuous electromagnetic signals over a period (seconds, minutes, or hours) using a transducer.

On the other hand, transient immunity tests like Electrostatic Discharge (ESD), Surge, Electrical Fast Transients (EFT), involves application of slow (Surges) and fast transient electromagnetic signals/waveforms (EFT & ESD) to the product.

Surge Immunity Testing and Voltage Dips/Brownouts Testing

The purpose of surge immunity testing is to determine how your product reacts to low-frequency power surges. These tests are mainly applicable to a product’s power & IO ports. These tests follow IEC/EN61000-4-5 standard and simulate occurrences such indirect lightning strikes, insulation faults, and switching events in a power distribution network.

Tests may also be required to assess your product’s response to dips, drops, and interruptions of voltage for both DC and AC power supplies. These tests follow IEC/EN 61000-4-11 for AC power and IEC/EN 61000-4-29 for DC power supplies. These simulate occurrences such as load switching and fault clearances in a power distribution network.

ESD Immunity Testing

ESD (ElectroStatic Discharge) tests are almost always required when it comes to immunity testing. These tests fall under the category of transient immunity and are heavily dependent on environmental factors such as relative humidity. ESD testing is performed according to IEC/EN 61000-4-2 which is a system level ESD standard and simulates ESD events directly to an electronic product or through a nearby metallic surface.

Conducted and Radiated Immunity

Conducted and Radiated Immunity tests fall under the Continuous EM Phenomenon category.

Conducted immunity tests are performed according to IEC/EN61000-4-6 while Radiated Immunity Testing is performed according to IEC/EN61000-4-3. The purpose of these tests is to simulate the effect of RF fields from other RF sources like intentional transmitters. You would be surprised at how many different sources of electric fields your device may encounter during normal usage. The main coupling mechanism of interest for the conducted immunity tests are the cables attached to the products.

Magnetic Field Immunity Testing

There are some immunity standards which will also require magnetic field testing to be performed according to IEC/EN61000-4-8. These tests investigate how your products react in the presence of magnetic fields such as those that may be generated by nearby power cabling. During these tests, your product will be subjected to electromagnetic disturbances at power frequencies(50/60Hz).

Why Choose Eurofins E&E North America?

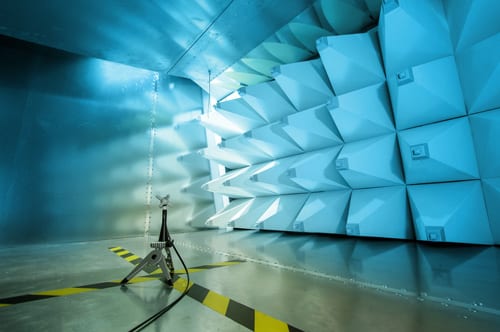

Eurofins E&E can perform EMC immunity testing to a wide array of standards. We offer a full suite of compliance testing tailored to meet your product’s needs. We also offer pre-compliance testing to help speed your product’s entry to market more efficiently by avoiding any last-minute complications. Our EMC testing facilities include 3-, 5-, and 10-meter semi-anechoic chambers, a reverberation chamber, and open area test sites (OATS).

We not only perform testing in our own lab , but can also support in-situ/on site EMC testing as well.

Our state-of-the-art testing lab is run by compliance experts, this allows us to thoroughly test and certify your products and devices for essentially any market.

We are a ISO 17025 A2LA accredited laboratory with a vast EMC scope including accreditation for FCC, Industry Canada (IC), Taiwan’s BSMI, Australia’s ACMA, Korea’s RRA, Japan’s VCCI, and Vietnam’s MIC.

In addition, we also operate as a notified body for the RED Directives.

All of our EMC testing projects are guided by an experienced lead EMC engineer. That engineer assumes responsibility for the entire project and works with a project manager who assists with scheduling the tests all the way through documenting your final report. Our team is there every step of the way, from pre-compliance through the testing and certification process. If your product fails to meet specifications, our engineers can provide guidance on what modifications your product needs in order to be in compliance. Contact us today.